The main reason electric vehicles (EVs) have not completely dominated the transportation sector is the current limitations of their high-voltage batteries. Despite significant advancements in the last decade, the energy content of these batteries remains far lower than that of liquid fuels. Achieving a battery with significantly higher energy density is the primary goal of automotive research. In this article, we will review the existing and promising upcoming battery technologies to keep you informed.

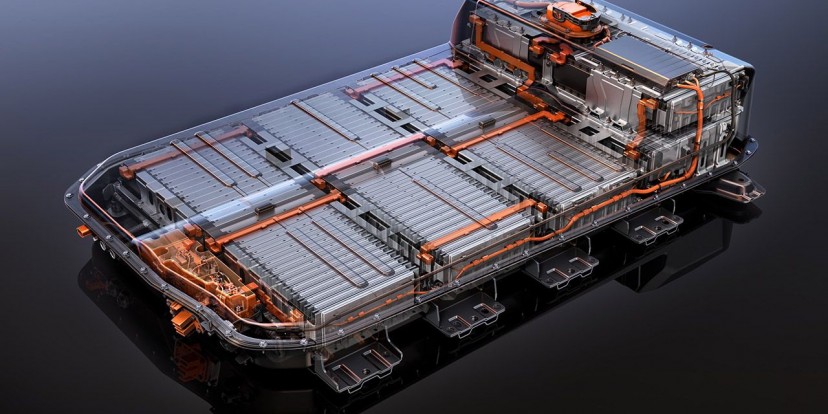

Lucid Air's advanced high voltage battery pack

Lucid Air's advanced high voltage battery packCurrent Technologies

Lithium-Ion: NCM and NCA Cathodes

Lithium-ion batteries originated about 30 years ago when Sony launched them in commercial devices, such as the Sony CCD-TR1 camcorder. These batteries operate by allowing lithium ions to move between the anode and cathode. During discharge, lithium ions travel from the anode to the cathode through liquid electrolytes, while electrons move through an external circuit and recombine at the cathode. The reverse process occurs during charging.

| Battery type | Li-ion NCX |

|---|---|

| Specific energy (Wh/kg battery) | 150-325 (High Nickel cathode, cell to pack, silicone anode) |

| Battery endurance (cycles) | 500-1500 |

| Total battery pack cost (€/kWh) | 250-280 |

| Required battery weight for a 500 km trip at 130 km/h with an average consumption of 25 kWh/100 km (kg) | 385-830 |

Today, lithium-ion NCM and NCA batteries are predominantly used in electric vehicles. The letters represent different materials: N for Nickel, C for Cobalt, M for Manganese, and A for Aluminum. Different ratios of these materials yield various battery characteristics. For instance, an NCM 712 battery consists of 70% Nickel, 10% Cobalt, and 20% Manganese. Generally, higher Nickel content results in increased energy density, positively affecting the battery pack’s weight and dimensions.

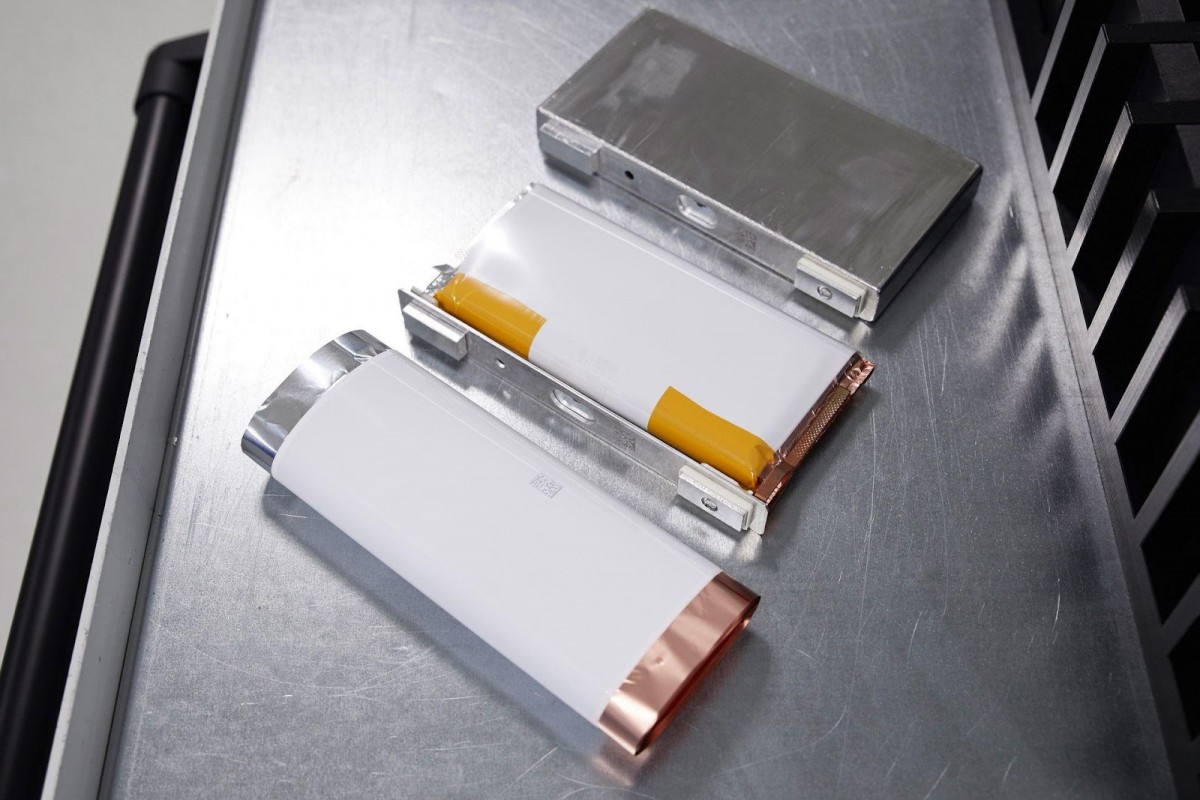

LG Chem NMC pouch cell

LG Chem NMC pouch cellDue to the scarcity of Cobalt and ethical concerns surrounding its mining (including child labor), manufacturers are striving to utilize chemistries with less or no Cobalt. A combination of high Nickel cathodes, cell-to-pack arrangements, and silicon anodes can elevate energy density to around 325 Wh/kg, indicating that this battery type is nearing its technological limits.

Lithium-Ion: LFP Cathodes

Another alternative for lithium-ion batteries is Lithium Iron Phosphate (LFP). While LFP batteries generally underperform compared to NMC types, they are favored by some manufacturers for their longer service life and the use of cheaper, more abundant materials. Their specific energy density is lower for two primary reasons.

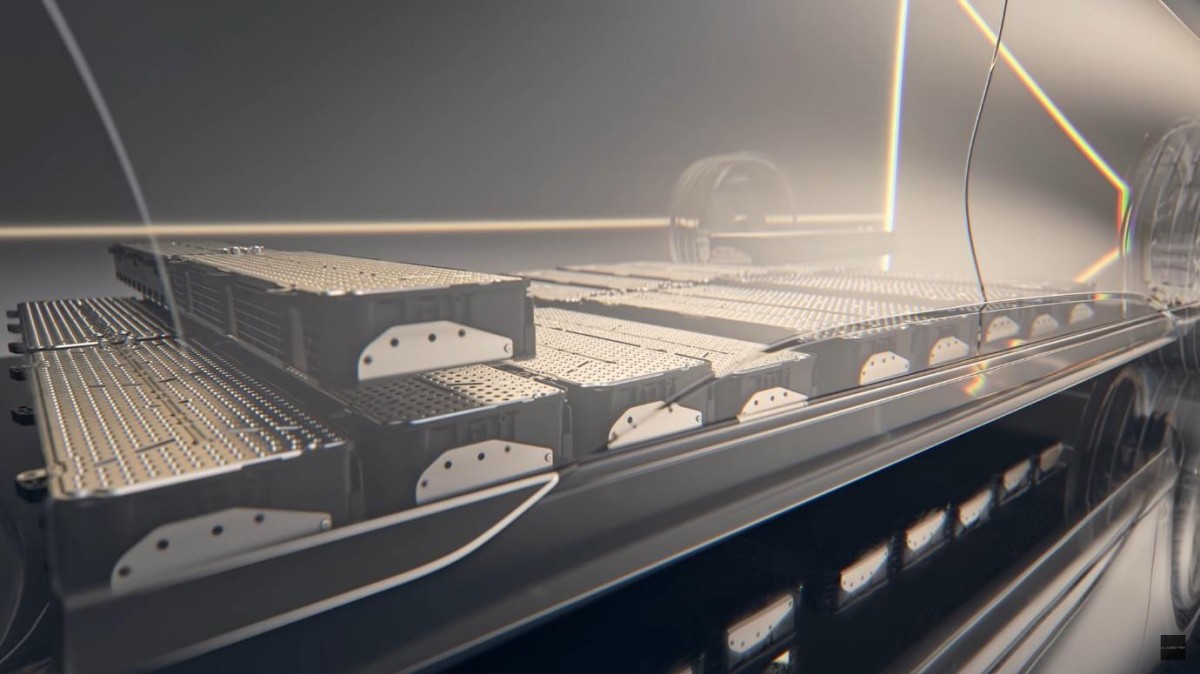

CATL manufactured LFP battery pack from Tesla Model 3

CATL manufactured LFP battery pack from Tesla Model 3Firstly, LFP batteries have a lower maximum voltage, which limits their capacity. Secondly, the lithium ions move in only one spatial dimension, compared to two dimensions in NMC batteries, reducing the maximum discharge power. Consequently, LFP batteries are not suitable for high-performance applications.

| Battery type | LFP |

|---|---|

| Specific energy (Wh/kg battery) | 120 |

| Battery endurance (cycles) | >2000 |

| Total battery pack cost (€/kWh) | 200 |

| Required battery weight for a 500 km trip at 130 km/h with an average consumption of 25 kWh/100 km (kg) | 1040 |

This is why Tesla employs this battery chemistry only in the base version of the Model 3. However, LFP batteries have two major advantages: they offer greater longevity than other Li-ion types and can be charged to 100% without issues; in fact, this is recommended for their optimal performance.

Emerging Technologies

Lithium-Air

Lithium-Air batteries are mostly in the research phase but hold tremendous promise, showcasing specific energy capabilities similar to those of liquid fuels with a remarkable 11.4 kWh/kg. In this battery type, lithium serves as the anode while air acts as the cathode, separated by an electrolyte. During discharge, lithium ions transition from the anode to the cathode, where they react with oxygen in the air.

| Battery type | Lithium-Air |

|---|---|

| Specific energy (Wh/kg battery) | 11400 |

| Battery endurance (cycles) | Very low |

| Total battery pack cost (€/kWh) | Unknown |

| Required battery weight for a 500 km trip at 130 km/h with an average consumption of 25 kWh/100 km (kg) | 11 |

Unfortunately, high temperatures during charging hinder rapid recharging, and dendrite formation during this process significantly reduces the battery's lifespan, confining its use primarily to laboratory settings. If technological hurdles are overcome and costs become feasible, this innovation could render internal combustion engine (ICE) vehicles obsolete overnight.

Solid-State Batteries

Solid-state batteries are considered the Holy Grail of automotive batteries, and extensive research is being conducted by major players in the automotive industry. Currently, conventional lithium-ion batteries deploy liquid electrolytes separated from the anode and cathode. In contrast, solid-state batteries replace the liquid electrolyte and separator with a solid electrolyte.

| Battery type | Solid State |

|---|---|

| Specific energy (Wh/kg battery) | 500-600* |

| Battery endurance (cycles) | 1000* |

| Total battery pack cost (€/kWh) | Unknown |

| Required battery weight for a 500 km trip at 130 km/h with an average consumption of 25 kWh/100 km (kg) | 200-250 |

Various materials, from metals to ceramics, are being evaluated as candidates for solid electrolytes. No electric vehicle currently employs this type of battery, but the first production models are anticipated within the next 2-3 years. Projected figures suggest that the specific energy density of these batteries could be double that of conventional lithium-ion batteries with liquid electrolytes, enabling around 1000 cycles, although these projections may improve over time.

BMW solid state battery cell

BMW solid state battery cell