The limited energy density of high-voltage batteries remains a primary barrier to electric vehicles (EVs) fully replacing traditional internal combustion engines. Despite significant advances over the past decade, current battery technologies still cannot match the energy content of liquid fuels. This overview explores the leading and emerging battery chemistries shaping the EV landscape.

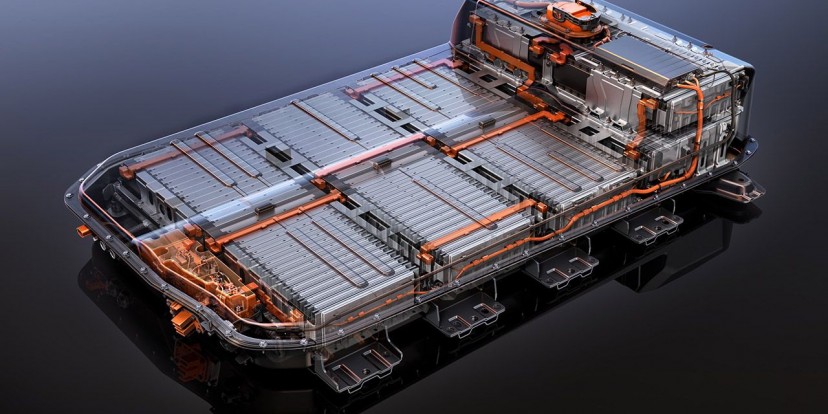

Lucid Air's advanced high voltage battery pack

Lucid Air's advanced high voltage battery pack

Current Battery Technologies

Lithium-ion Batteries: NCM and NCA Cathodes

Lithium-ion batteries date back nearly 30 years, first commercialized by Sony in the CCD-TR1 camcorder. They operate by shuttling lithium ions between the anode and cathode through a liquid electrolyte; electrons flow via an external circuit, enabling charging and discharging processes.

| Battery Type | Li-ion NCM/NCA |

|---|---|

| Specific Energy (Wh/kg) | 150–325 (High-nickel cathode, cell to pack, silicon anode) |

| Battery Endurance (cycles) | 500–1500 |

| Total Battery Pack Cost (€/kWh) | 250–280 |

| Battery Weight Needed for 500 km Trip (@130 km/h, 25 kWh/100 km) | 385–830 kg |

NCM and NCA battery chemistries dominate current EVs. “N” stands for Nickel, “C” for Cobalt, “M” for Manganese, and “A” for Aluminum. The percentage composition defines battery characteristics; for example, an NCM 712 battery contains 70% Nickel, 10% Cobalt, and 20% Manganese. Higher nickel content increases energy density, reducing weight and size.

LG Chem NMC pouch cell

LG Chem NMC pouch cell

Due to cobalt’s scarcity and ethical concerns, manufacturers aim to reduce or eliminate its use. Combining high-nickel cathodes with silicon anodes and optimized cell-to-pack designs can push energy density up to 325 Wh/kg, nearing current technological limits.

Lithium-ion Batteries: LFP Cathodes

Lithium Iron Phosphate (LFP) is another cathode chemistry choice. Although LFP batteries generally have lower energy density than NCM types, they offer longer service life and rely on more abundant, affordable materials.

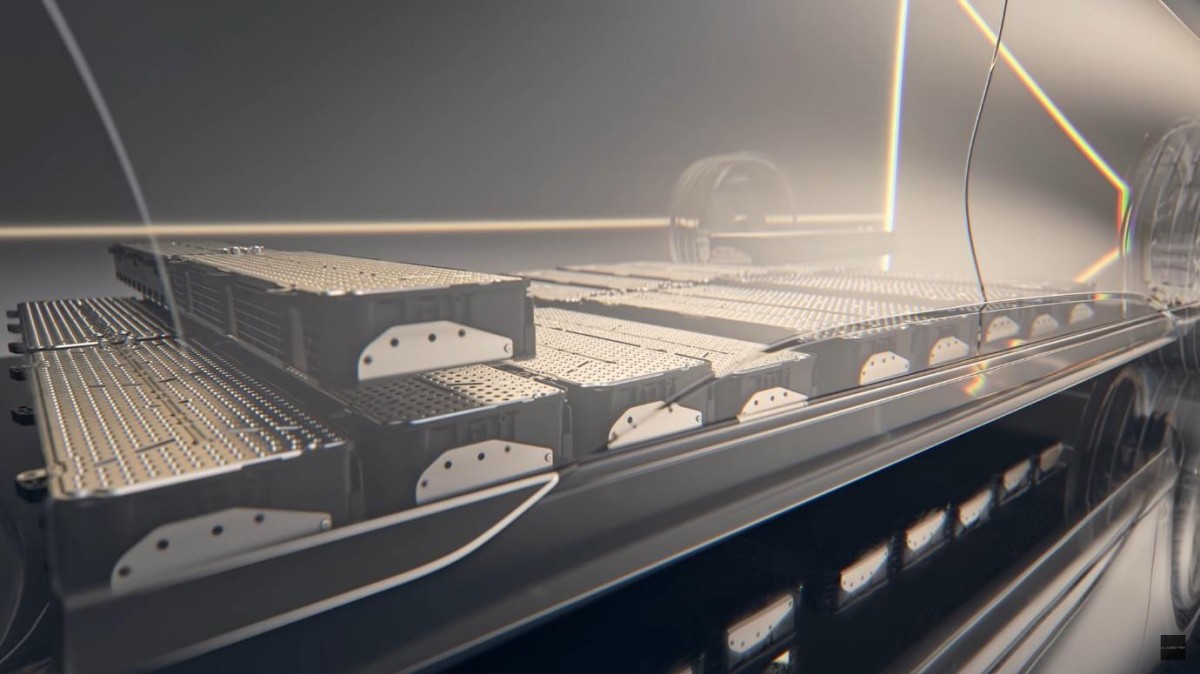

CATL manufactured LFP battery pack from Tesla Model 3

CATL manufactured LFP battery pack from Tesla Model 3

LFP batteries have lower maximum voltage and lithium ions diffuse along only one spatial dimension, limiting both energy density and maximum discharge power. This makes LFP less suitable for high-performance EVs but ideal for base models, such as Tesla’s entry-level Model 3, due to its superior longevity and ability to be safely charged to 100% capacity.

| Battery Type | LFP |

|---|---|

| Specific Energy (Wh/kg) | 120 |

| Battery Endurance (cycles) | Over 2000 |

| Total Battery Pack Cost (€/kWh) | 200 |

| Battery Weight Needed for 500 km Trip (@130 km/h, 25 kWh/100 km) | 1040 kg |

Emerging Battery Technologies

Lithium-Air Batteries

Lithium-Air batteries are currently experimental but highly promising, boasting theoretical specific energy near 11,400 Wh/kg—comparable to liquid fuels. Their structure uses lithium in the anode and oxygen from the air at the cathode, separated by an electrolyte. During discharge, lithium ions combine with oxygen.

| Battery Type | Lithium-Air |

|---|---|

| Specific Energy (Wh/kg) | 11,400 |

| Battery Endurance (cycles) | Very low |

| Total Battery Pack Cost (€/kWh) | Unknown |

| Battery Weight Needed for 500 km Trip (@130 km/h, 25 kWh/100 km) | 11 kg |

Unfortunately, challenges such as high charging temperatures that prevent rapid recharge and dendrite formation reducing battery life currently limit Lithium-Air batteries to laboratory research. If these obstacles are overcome at reasonable cost, they could revolutionize transportation and render internal combustion engines obsolete.

Solid-State Batteries

Widely regarded as the ultimate advancement in automotive batteries, solid-state technology replaces the liquid electrolyte and separator with a solid electrolyte, enhancing energy density and safety.

| Battery Type | Solid-State |

|---|---|

| Specific Energy (Wh/kg) | 500–600* |

| Battery Endurance (cycles) | ~1000* |

| Total Battery Pack Cost (€/kWh) | Unknown |

| Battery Weight Needed for 500 km Trip (@130 km/h, 25 kWh/100 km) | 200–250 kg |

Various solid electrolytes—metallic or ceramic—are under investigation. Although no commercial EVs currently use solid-state batteries, the first production models are expected within 2–3 years. These batteries may double the energy density of conventional lithium-ion packs while maintaining respectable cycle life, with further improvements anticipated.

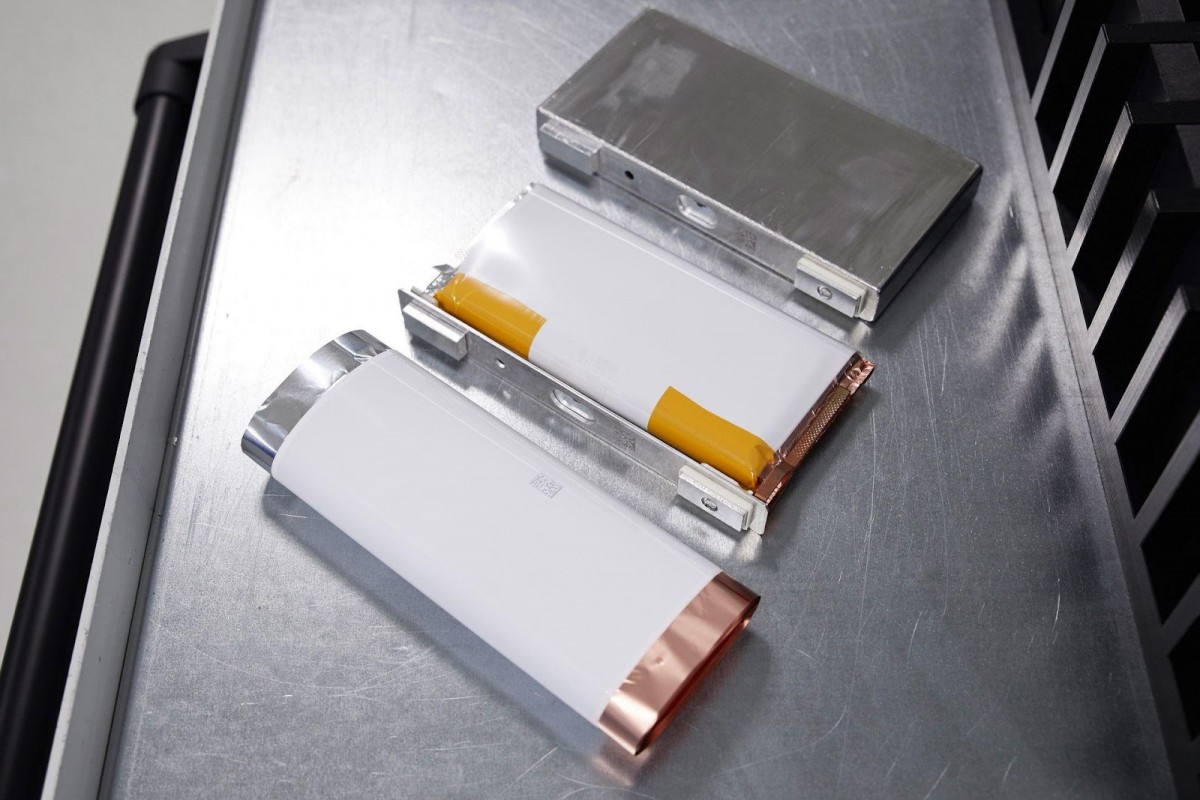

BMW solid state battery cell

BMW solid state battery cell