The vast majority of electric cars today do not utilize conventional gearboxes. There are three primary reasons for this, but first, it is essential to understand what a gearbox is and its function in internal combustion engine (ICE) vehicles. This context will help clarify why gearboxes are not crucial in electric cars, while also outlining scenarios where they can be beneficial.

Understanding Gearboxes in ICE Vehicles

ICE engines, unlike electric motors, lack sufficient torque at idle to initiate movement. Higher engine RPMs are necessary to generate more torque. However, the engine's RPM range is limited, which could restrict the vehicle's speed, necessitating the use of gearboxes. Essentially, a gearbox, in combination with the final drive ratio, acts as a torque multiplier. You may have encountered the terms 'gear ratio' and 'final drive ratio' before, but let's clarify their significance.

Consider a scenario where you choose 1st gear in your ICE vehicle, which has a gear ratio of 3:1. This indicates that the engine's torque is tripled. To find out how this torque multiplies at the wheels, we also incorporate the final drive ratio. For instance, if the final drive ratio is also 3:1, then the wheel torque becomes nine times the engine torque. If the engine produces 200 Nm of torque in 1st gear under these ratios, the wheel torque becomes 200 Nm x 9 = 1800 Nm.

Without a gearbox, such torque multiplication would be impossible, and the vehicle would remain motionless even with full throttle. The design of a gearbox in an ICE vehicle aims to optimize the engine's power and torque characteristics, efficiency under varying loads, and the maximum speed specified by engineers.

Despite significant advancements over the years, these solutions still involve compromises. Gearboxes introduce inefficiencies into the drivetrain, leading to increased fuel consumption and energy losses.

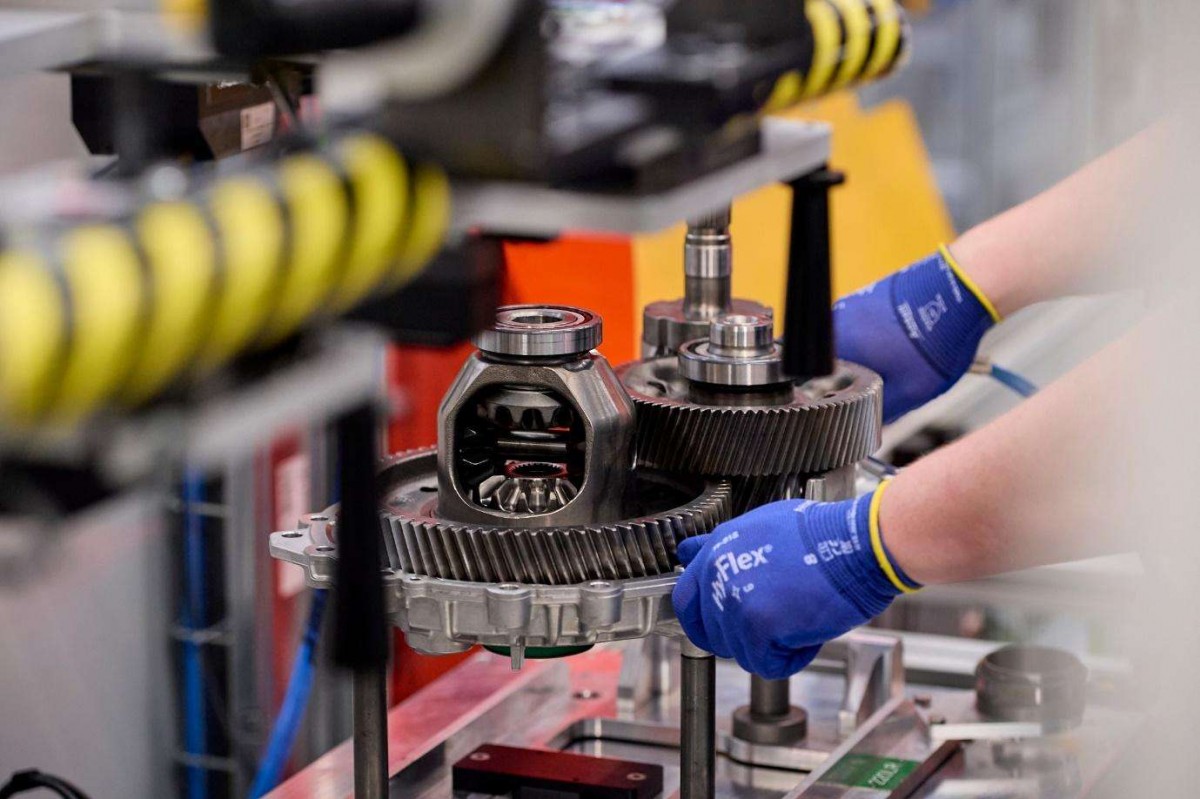

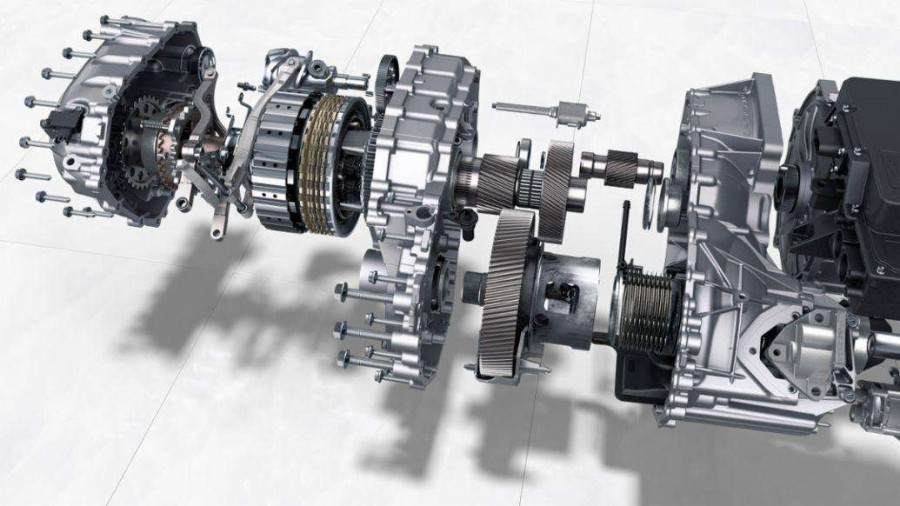

Modern automatic gearbox with 9 gears. The ZF 9HP.

Modern automatic gearbox with 9 gears. The ZF 9HP.Gearboxes and Electric Cars

Electric motors possess three inherent properties that address engineering challenges related to gearbox development, making them largely unnecessary. These properties include high torque from zero RPM, the ability to achieve high RPM, and electronically governed top speeds. Let’s explore each of these properties.

The advantage of high torque from zero RPM is clear. Since gearboxes primarily function as torque multipliers, having high torque from the start eliminates the need for multiple gear ratios.

Equally important is the ability of electric motors to reach up to 20,000 RPM, providing sufficient torque across the range to achieve top speeds with just a single gear ratio. The electronically controlled top speed of electric vehicles is the final factor; this limitation arises not just from the absence of a gearbox, but also due to the comparatively lower energy density of current high-voltage batteries versus traditional liquid fuels.

To illustrate, consider the BMW i4 eDrive 40, which generates a maximum motor torque of 430 Nm from 0 to 5000 RPM, with a combined gear and final drive ratio of 11.115:1. This results in a wheel torque of 4780 Nm, showcasing why electric vehicles excel at quick starts from a standstill.

Your typical top speed for this car is 190 km/h, with the motor running at 16,500 RPM. At highway speeds of 130 km/h, the motor operates at about 11,300 RPM. This example demonstrates how the electric motor's RPM range meets all performance criteria without necessitating a gearbox.

The single-speed gearbox of the BMW i4.

The single-speed gearbox of the BMW i4.The Porsche and Audi Approach

The Porsche Taycan and Audi E-Tron GT feature a rear motor equipped with a two-speed gearbox. This may seem contradictory to our earlier discussion on the lack of necessity for gearboxes in electric vehicles. However, the rationale for a two-speed gearbox lies in the desire to have a shorter gear ratio for improved acceleration at low to medium speeds and a longer gear ratio for higher speeds, which reduces the motor's RPM.

Reducing the motor’s RPM at higher speeds serves two purposes: it enhances efficiency by minimizing back EMF and eddy currents, which consequently improves the vehicle's range. Additionally, it allows for higher top speeds without subjecting the motor to excessive rotational speeds.

Nevertheless, implementing two-speed gearboxes presents technical challenges due to the immense torque electric motors generate instantaneously. Some manufacturers are actively working on developing reliable two-speed gearboxes for electric cars.

If successful in producing these gearboxes at scale with robust reliability and reasonable costs, we may see broader adoption beyond high-performance models like the Porsche Taycan and Audi E-Tron GT. At present, however, the complexity and cost advantages do not justify widespread use.

Porsche Taycan’s two-speed gearbox

Porsche Taycan’s two-speed gearbox